PD Plus Blowers

Air and gas blower, rated up to 18 PSI / 17 "Hg vac. Premium blowers renowned for their quality, dependability and outstanding performance.

Vertical & Horizontal Air Flow

This series has wide application in pneumatic conveying, wastewater treatment, and the general process industry where high pressure, high volume air is required. Seal areas are vented to atmosphere to relieve process pressure against the internal lip seals, and to provide oil-free air.

Vertical & Horizontal Single Envelope Gas Service

This series is utilized in such applications as closed loop pneumatic conveying, process gas handling, or elevated pressure applications up to 100 PSIG discharge. Vent openings are tapped and plugged to prevent gas leakage. These fittings can also accept an inert gas purge for positive containment of the process gas.

Vertical & Horizontal Double Envelope Gas Service

This series is built to laboratory standards where virtually complete sealing is required. In addition to the features shown on the above series, the drive shaft is mechanically sealed and the oil sumps are plugged to provide an even higher degree of leakage protection.

CP Series Blowers

M-D Pneumatics™ rotary positive displacement blowers combine rugged performance with flexibility as drop-in replacements to fit a variety of applications. CP Series blowers can be field converted from horizontal to vertical flow, or vice versa, without any special tools or additional components. CP Series rotary blowers are designed to be interchangeable with equivalent sizes of Roots Universal RAI® and many Sutorbilt® Legend® blowers.

Constant Protection: Standard on all models, triple lip seals extend the life of the seal and have been shown to provide longer bearing life. Magnetic drain plugs keep particles from moving through bearings and seals.

Stronger Bearings: All CP Series blowers include double-row ball bearings at the gear end, stronger than single-row ball bearings offered by other manufacturers. Drive shaft bearing is cylindrical roller type for additional strength against side loading from V-belt drives. CP Series bearing life is as much as 50% greater than models offered by other manufacturers.

Helical Gearing: CP Series blowers are timed with precision helical gears keyed to the rotor shafts, not taper-fit spur gears as offered by other manufacturers which have greater backlash, can slip and lose timing. Helical gears are also quieter, reducing mechanical noise.

Lubrication: Many CP Series models include dual oil splash lubrication at both the gear end and drive end of the blower. Splash lubrication provides for longer bear-ing and seal life through improved heat dissipation versus grease lubrication.

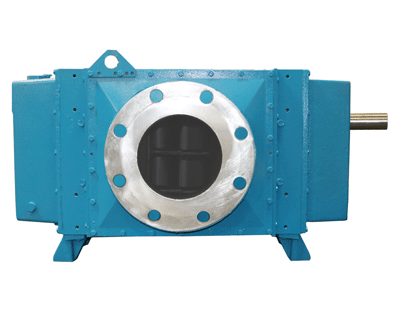

Positive Displacement Blowers

QX Blowers

The MD Pneumatics Qx is a high pressure, low noise industrial blower that provides high efficiency at high pressure and vacuum. Its bi-direction, tri-lobe rotor design offers reduced pulsation and lower noise levels while its large integral shaft rotors prevent loosening over time.

Helical Gearing: Qx blowers utilize precision helical gears, keyed to the rotor shafts. Helical gears are quieter reducing mechanical noise.

Stronger Bearings: QX has larger bearings than any other blower in same gear sizes which can lead to longer life, offering L10 bearing life of up to 200,000 hours. They include double-ball bearings on the timing gear end. For additional strength, single roller bearings are used on the drive shaft end of the machine.

Lubrication: Qx blowers have oil lubrication on both ends with easy to view sight glasses allowing quick maintenance.

Seals: Qx blowers are fitted as standard with piston ring labyrinth process/oil seals. Piston ring seals provide high efficiency, long life and reliability. The oil chamber is vented to atmosphere providing oil-free air.

Equalizer Blowers

Equalizer blowers are designed drop-in replacements for most competitive models, available in RM and DF configurations.

Higher Pressure Capability: Most models are rated to 18 PSIG discharge pressure. This provides you with an increased level of security due to built-in safety factors.

Designed for True, Drop-in Replacement: Dimensionally interchangeable with competing models, even to the point of matching the port connector bolt patterns.

Helical Gearing: Helical gearing reduces backlash and mechanical noise as compared to spur gears offered by other manufacturers.

Rotors with Integral Shafts: Precision machined and dynamically balanced ductile iron rotors with large, integrally cast shafts to provide single, unitized rotors to prevent clash as a result of the impeller moving on its shaft.

Positive End Clearances: End clearances are positively established (versus floating) at the blower gear end, eliminating the risk of shifting end clearances that reduce unnecessary rotor and end plate wear. This design improves flow performance and extends overall blower life.

Polished Sealing Surfaces: All shaft surfaces in contact with sealing members are polished to reduce seal wear and risk of leakage.