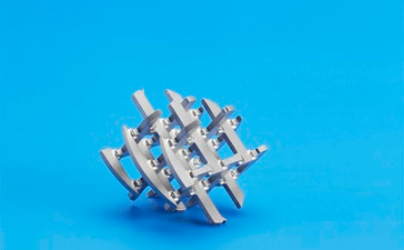

Sulzer KVM and SMI Mixers

The KVM mixer features a pressure drop of only 11’’ of water column at 5 ft/sec. It can mix additives introduced upstream of the mixer or mix additives injected directly in front of the first mixing element. In order to allow the injection of multiple additives, the KVM mixer can also be supplied with multiple injection port connections. The KVM mixer allows mixing of additives without a sparger.

The geometry of both mixer types has been optimized with the help of CFD simulation. The mixing elements create large counter rotating vortices and ensure efficient mixing over the entire cross section of the pipe. The static mixer type SMI is mainly sold in Europe and Asia, whereas the KVM type is the standard product for the North and South American market. The SMI mixer has an open structure, which eliminates the risk of clogging.

Static Mixers

Sulzer SMX Mixers

The standard SMX mixer was developed by Sulzer and assumed over many long years the position of the standard equip-ment in mixing of viscous liquids. Owing to the continuing pursuit for further development with most advanced simulation techniques and complex test series Sulzer is now pleased to present the new revolutionary SMX plus generation of mixers. The SMX plus mixer excels with most efficient homogenization at some 50% of the usual pressure drop.This dramatic pressure drop reduction results in number of different advantages for users. Depending on the application either smaller pumps with lower energy consumption can be used or much smaller mixers could be designed, possibly leading to reduced size of the whole plant. The possibility of performing a mixing duty with a smaller mixer and strongly reduced residence time can be advantageous for cases where product degradation is a problem.

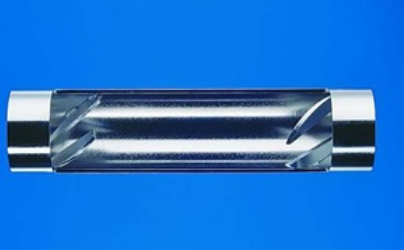

Sulzer SMV Mixers

The Sulzer SMV static mixer is ideal for applications that require a distributive and homogeneous mixing and blending action in the turbulent flow regime. Typical uses for the Sulzer SMV static mixer are applications requiring dispersive mixing or mass transfer in the turbulent flow regime. This occurs typically between immiscible phases where an interfacial tension exists. Examples are oil/water or gas/liquid systems. Higher shear forces are required for this dispersion task.